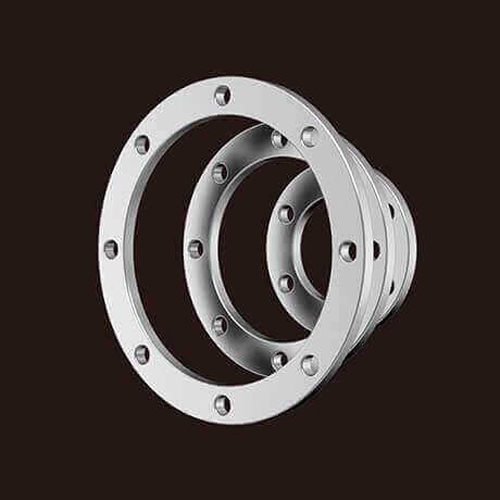

HK40 SS310 Pipe Centrifugal Casting

31000 INR/Number

Product Details:

- Product Type Cast Products

- Material Stainless Steel

- Surface Finishing Polished

- Weight 30 Kilograms (kg)

- Color Silver

- Click to View more

X

HK40 SS310 Pipe Centrifugal Casting Price And Quantity

- 31000 INR/Number

- 9 Piece

HK40 SS310 Pipe Centrifugal Casting Product Specifications

- Polished

- Silver

- 30 Kilograms (kg)

- Cast Products

- Stainless Steel

HK40 SS310 Pipe Centrifugal Casting Trade Information

- Fob port

- 40 Piece Per Month

- 3 Week

- Sample costs shipping and taxes has to be paid by the buyer

- wooden

- Middle East Central America North America South America Asia Africa Australia Eastern Europe Western Europe

- All India

- ISO

Product Description

HK40 SS310 Pipe Centrifugal Casting is a specialized manufacturing method for producing high-quality, seamless metal pipes with exceptional performance characteristics. This technique excels in creating pipes of various sizes, from small tubing to large industrial pipelines. The process begins by melting the chosen metal and preheating a cylindrical mold, which is often lined with refractory material to withstand high temperatures. Molten metal is poured into the rapidly rotating mold, subject to controlled centrifugal force, ensuring uniform distribution and minimizing defects. The resulting pipes feature consistent wall thickness, excellent mechanical properties, and a smooth inner surface finish. Pipe centrifugal casting is extensively used in industries like construction, petrochemicals, and infrastructure development, providing durable and reliable piping solutions.

Enter Buying Requirement Details

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free